What Are Eva Films?

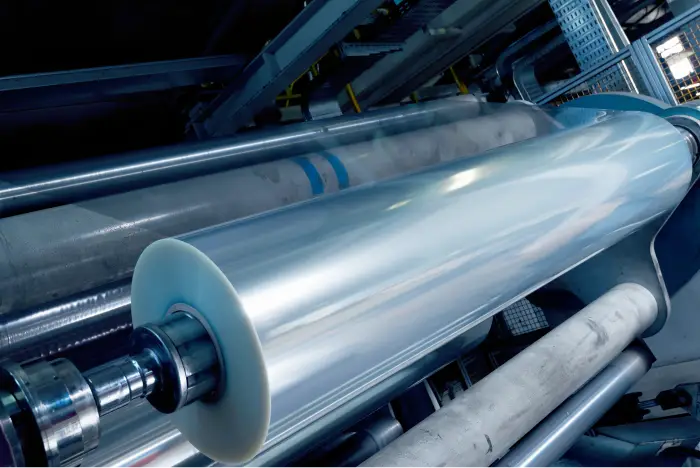

Ethylene Vinyl Acetate Film for Solar Panel Lamination & More

EVA film, short for ethylene vinyl acetate, is a highly versatile material widely used in solar panel lamination and various other industrial applications.

Its durability, flexibility, and strong adhesive properties make it an essential component in many manufacturing processes.

If you are interested in EVA film for your industrial applications, we encourage you to contact us today. Our team is ready to provide you with detailed information about our EVA films and discuss our custom manufacturing capabilities to meet your specific needs.

Cross-Linkable EVA in Solar Encapsulation

Essential for Solar Panels, but Requires UV Protection

Cross-linkable EVA is the most common encapsulation in the solar industry. The cells are laminated between films of EVA in a vacuum with the help of a lamination machine, which is under compression.

This procedure is conducted under temperatures of up to 150°C. However, one of the disadvantages of EVA films is that it is not UV-resistant. Due to this aspect, protective front glass is required for the UV screening during installation. For standard modules that use EVA encapsulation, the backing usually is a layer of PVF film, PET film or metal. Commonly referred to as Tedlar composite.

When applied properly, EVA lowers the seal initiation temperature and melting point of PE film. In low percentages, EVA has been used for decades for enhancing sealing ability for bread bags, ice bags and frozen food packaging. In higher percentages, more or less 20% EVA, it is used for low melt/total batch inclusion bags. In the end, the higher percentage EVA, the lower the melting point whether measured as DSC melting point.

Higher percentage EVA’s are soft and tacky and solar panels require a bonding layer. The resin of choice has emerged as 33% EVA. It is too sticky to make into film and must be made by the case process. EVA has a pungent, apple vinegar odor which can transfer to foods especially dairy products, so it is not ideal for that application. EVA is considered obsolete by many for packaging applications since metallocene offers faster hot tack. However, demand for EVA remains strong for PVC replacement.

EVA Film Details

Ensures Durability, Bonding, and Optical Clarity

Once laminated, EVA film serves as a critical barrier against humidity and dirt while also cushioning solar cells to absorb shocks and vibrations. This protective layer ensures the longevity and efficiency of solar panels. The standard layering process includes glass, EVA film, solar cells, another EVA film layer, and a Tedlar composite backing.

Key Properties of EVA Film:

- Durability: Resistant to high temperatures and humidity, ensuring long-term performance.

- Bonding: Adheres well to textured solar glass and back sheets for secure encapsulation.

- Optical Clarity: High transparency allows optimal sunlight transmission to solar cells.

EVA Film vs. PEVA: Understanding the Terminology

EVA (Ethylene Vinyl Acetate) and PEVA (Polyethylene Vinyl Acetate) are the same material. The addition of “polyethylene” in the name has led to misconceptions, but both terms refer to the same copolymer, commonly used in solar panel encapsulation.